FOCUS ON PACQUET INSTALLATION : SAFETY ON TANKER TOP

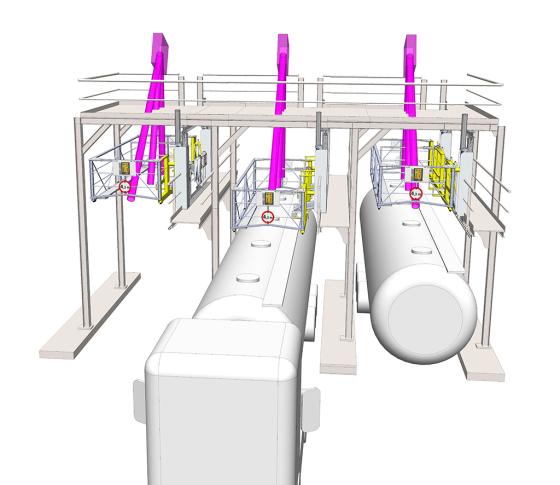

Pacquet responded to the problems encountered in an application for loading activated carbon into industrial filters. Pacquet designed and installed three MTB evo model Lift & Lower walkways on three separate loading tracks. Let's take a look back at this achievement which has the particularity of being suspended.

Our client had created its own access security system many years ago, but it did not work. They therefore called on Pacquet to design a new system, with whom he had already established a relationship of trust following a previous successful installation of a security station with telescopic sleeve for single-tanks.

Integration to an existing environment

After having proven the effectiveness of its secure station, Pacquet was requested to secure access to tanker tops as part of activated carbon loading operations. “Our client called us to analyse the issue that they had been facing. We had to take into account a complex environment, including little available floor space and a very dusty atmosphere.

We went to the site to carry out an in-depth survey, then we carried out a pre-study with 3D plans which demonstrated that our equipment could be integrated into their installation. »

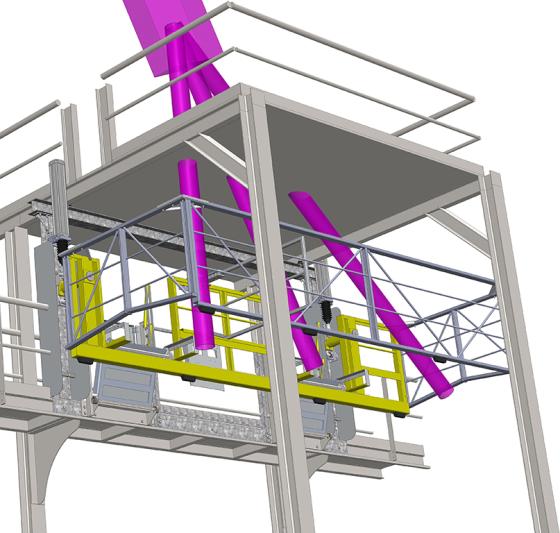

The great particularity of the project was therefore being able not to put anything on the ground. Pacquet Solutions d’Empotage has made every effort to suspend its walkways via fasteners on all structural elements at height. “We had already encountered this same type of constraints in candy, and we had already made suspended versions of our access walkways. We carried out load reduction calculations on site, which we provided to the client to ensure that their structure was capable of supporting the weight of the installation. »

Installation specificities

- Suspended version with absence of supporting structure

- Dual dome access on either side of a single control panel

- The gateway is installed on the customer's existing platform

- Gateway adapted to the multiple typologies of tanks encountered

A secured and ergonomic installation

With no possible footprint, Pacquet therefore produced the elements necessary to integrate perfectly into the existing installation. The installation was carried out in three stages, on three loading tracks.

“Each time we intervened on site, we always gave the client the opportunity to work on the two other tracks on which we did not intervene. It was imperative for the client to be able to keep on working.

The gangway provides real comfort of use for the operator: access from the right or left side, pneumatic control, and therefore with pneumatic cylinder, tilting, arch perfectly placed on all the filters…” The proposed solution also offers a significant saving of floor space and allows, among other things, to avoid the risk of collisions when maneuvering trucks. pacquet potting solution adds that “trucks travel a lot to deliver to many sites, and rain or snow can, for example, make the floors slippery and pose risks for the operator. » The client subsequently wishes to increase its production capacity by manufacturing a fourth track, and therefore wishes to once again call on Pacquet to equip it. “This achievement was a great challenge for us.”

Handling a dusty atmosphere

One of the very important parameters to be analysed for this application was to take into account the very dusty atmosphere of the site. To guarantee the proper functioning of the system, this required the integration of adequate protection, such as casings in particular. As for the cylinders, they were made with a stainless steel rod and were equipped with protective bellows so as not to hinder the sliding elements.

New projects are on !

The success of the installation carried out on site led the customer to place a new order with the company to, this time, secure an access station. Previously, the operator was on a concrete access ramp to carry out loading via forklifts. The customer asked Pacquet to allow the operator to access the access walkway from its ramp. “We proposed a platform that goes over the truck,” explains the operational director. This allows the operator to move from one side of the truck to the other, without having to cross the floor passage. The client will dismantle the entire existing installation and create concrete blocks so that we can then install our elements. »