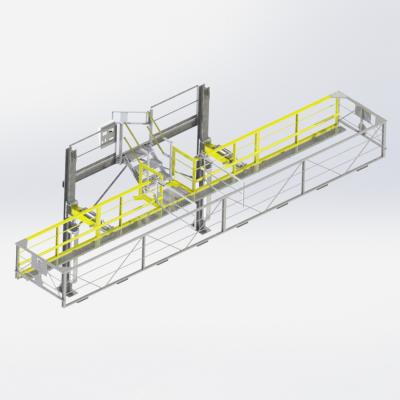

MONTE ET BAISSE TANKER TOP LOADING SYSTEM

For the top loading of multi-compartment tankers

A gangway that can be adjusted to fit almost every tanker or ISO container

This significantly reduces the risk of falls: a clearly marked-out area for working at height that fits very close to the tanker

Strengths and specificities

The gangway's safety cage fits closely to the tanker, marking out a very safe tanker top working perimeter: it goes up, down, tilts and moves out until the work area is as safe as possible

A completely autonomous structure with an integrated staircase and platform

Available in a single and dual configuration with up to 4 loading arms or variable-reach top unloading arms

Conditions of use

Our Monte et Baisse gangways can be used with multiple configurations. Let's define together the tanker top Monte et Baisse gangway most suited to your installation.

MAIN FEATURES AND OPTIONS OF THE GANGWAY

- Front side of the hot-dip galvanised steel gangway - painted finish on request

- Temporary aluminium safety cage as standard - painted or stainless steel finish on request

- The length of the safety cage can be adjusted according to your needs - from 4 to 12 metres

- Width of the safety cage adjustable according to your needs from 1400 mm to 2000 mm - 2000 mm as standard

- Raising and lowering the temporary safety cage of the gangway

- Incline of the temporary safety cage

- The position of the fall protection system is adjusted using pneumatic actuators

- 3 or 4-step gangway stairs as requested

- The length of the steps can be adjusted according to your installation from 800 mm, as standard, up to 4000 mm

- Fall protection system available in a freestanding or hanging version, or integrated into the customer process

- Remotely controlled retractable sliding barriers

- Add a staircase, post, platform or even several variable-reach top loading arms: you get a Monte et Baisse® access system or Monte et Baisse® loading system (single or double)

- Will the Monte et Baisse® fall protection system be used for loading and unloading liquid or gaseous fluids? Do you already have a loading or unloading arm installed on your site? Bear in mind that any existing loading arms may not be compatible with the safe access gangway to be installed. Pacquet develops and designs all-inclusive loading systems with arms and tanker top access gangways. Contact us.

ON REQUEST:

- 3rd axis: in/out movement of the temporary safety cage of up to 400 mm

- Integration of false steps, depending on your installation (single or double, positive or negative, false step)

- Integration of a removable step

- Compressor option integrated in the gangway

- Locking in storage position

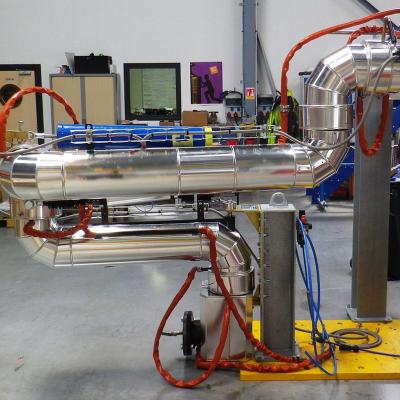

FEATURES OF THE VARIABLE-REACH TOP LOADING ARMS

Find all the information on the variable-reach top loading arms by clicking here

Specify ATEX zoning if applicable - CE marking for pneumatic, electrical equipment, or equipment used in ATEX zone

MORE THAN 180 TANKER TOP MONTE ET BAISSE® GANGWAYS ARE CURRENTLY IN SERVICE. YOU TOO CAN PREVENT FALLS FROM THE TOP OF TANKERS AND ADOPT THE MONTE ET BAISSE GANGWAY: CONTACT OUR TEAMS