SPARE PARTS STOCK MANAGEMENT, WORKSHOP ASSEMBLY AND TESTS

OPTIMISED MANAGEMENT OF SPARE PART STOCKS - LOADING ARMS, UNLOADING ARMS, TANKER TOP ACCESS PLATFORMS AND GANGWAYS

The ability to manage lead times is a constant concern. In order to save time and have a clear and efficient organisation, but also to minimise movements and the risk of Musculoskeletal Disorders (MSDs), Pacquet Solutions d'Empotage has invested in a storage warehouse with an automatic digital distribution system. There are many advantages to this system:

- A control screen which controls all the drawers connected to our CAPM (Computer Aided Production Management)

- Recording of the entire stock available in the fleet

- Real-time visibility of our spare parts stock with minimum/maximum stock alerts

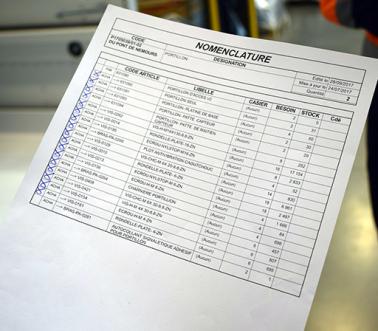

- Product nomenclatures recorded and constantly updated

- Responsiveness and increased productivity in following up and preparing our orders

Delphine, purchasing assistant and order picker

"Thanks to the digital warehouse, we no longer have to search for parts and we don't waste time. It is also used to manage the quantities. We can also prepare several drawers simultaneously so that, once the necessary parts are taken from the first drawer, the next one is already pre-positioned: a real time saving. Using the control panel, we can also list the large-sized items which are stored outside the storeroom directly in our warehouses. However, they are still physically available and recorded."

TRIAL ASSEMBLY AND TESTS: POST-MANUFACTURING INSPECTION TIME

Our sole objective: delivering equipment that complies with your approved need. We then conduct a full pre-assembly (trial assembly) of your arms and gangway as well as a series of tests before packaging and shipping. To finish: all the measurements are checked once again by the design office, photos are taken of the assembly and the details are recorded. Your equipment is now ready to be packed and delivered. Pacquet's support guarantees the following on commissioning:

- that the assembly is in perfect working order

- that none of the fittings or other elements are missing from the assembly

- that the displacement drawings are compliant

- that the facility is operational and ready to be put into service (supporting test results and inspection sheets)