BARGE LOADING ARMS, BARGE UNLOADING ARMS

For your waterway applications

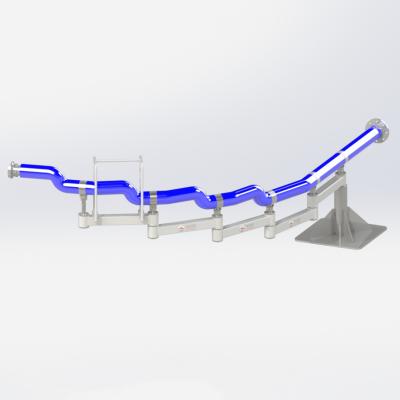

The loading and unloading arm made for barge and waterway applications

Avoids having to use of a long and heavy hose that is difficult to handle

Strengths and specificities

- For carrying out highly technical large-scale loading and unloading operations very easily

- All the axes can be automated, with full remote control capability

Conditions of use

The conditions of use depend on several factors (installation environment of the arms, service conditions and fluid characteristics). Let's find the right loading arm for you: send us your SDS (safety data sheets).

STANDARD TECHNICAL CHARACTERISTICS OF barge loading and unloading arm

- Steel or stainless steel construction as standard

- Balancing using gas-spring compensators as standard

- Side, right or rear barge connection

- Fastening to the ground or via a jetty (the Pacquet barge arm is delivered with a foot)

- Side feed

- Rigid connection at the end of the arm (maritime-type connection)

sectors

All sectors

APPLICATION EXAMPLES

- Loading and unloading edible oils

- Loading biofuel

- Unloading engine oils

optional equipment available

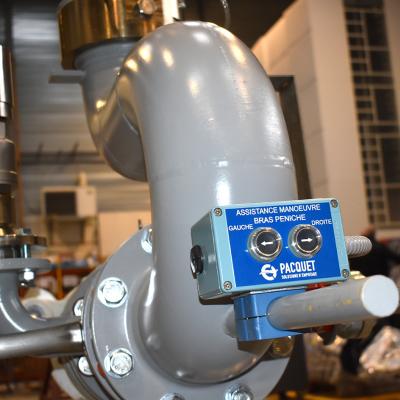

- Pneumatic assistance for rotating the arm with operating handles

- Vacuum breaker

- Single butterfly valve or double offset butterfly valve

- Ball valve

- Remotely controlled valve opening/closing control

- Drain valve

- Locking in storage position

- Position detector

- Electric tracing or double jacket heating of the arm (heat-transfer fluids)

- Thermal insulation

- Couplers for the connection to the top of the tanker

- Emergency disconnector

- Specific paint finish

- Specific coatings on request

- Atex archiving

Specify ATEX zoning if applicable - CE marking for pneumatic, electrical equipment, or equipment used in ATEX zone - Specify if the loading arm is subject to the EU pressure equipment directive