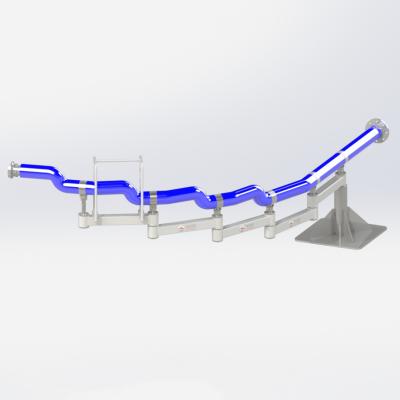

DOUBLE BOTTOM UNLOADING SYSTEMS LIQUID PHASE, GAS PHASE

Bottom unloading system with balancing arm

For unloading liquid fluids while balancing the pressure during unloading

A fully rigid and ergonomic structure using two bottom arms

Strengths and specificities

- Two-arm configuration that is more technical and more durable than an arm and hose configuration

- Bottom connection: the risk of falls from the top of the tanker is avoided

- Saves space in its stored position: the double arm system frees up floor space

Conditions of use

The conditions of use depend on several factors (installation environment of the arms, service conditions and fluid characteristics). Let's find the right loading arm for you: send us your SDS (safety data sheets).

STANDARD TECHNICAL CHARACTERISTICS OF THE double BOTTOM unloading system

- Steel or stainless steel construction as standard

- Balancing using gas-spring compensators as standard

- Side, right or rear truck connection

- Top, bottom or side feed

SECTORS

All sectors - gas applications included

optional equipment available

- Fastened with a support bracket

- Pneumatic assistance (helps with handling the loading arm) and remote control with reinforced sleeve

- Single butterfly valve or double offset butterfly valve

- Ball valve

- Remotely controlled valve opening/closing control

- Drain valve

- Locking in storage position

- Position detector

- Electric tracing or double jacket heating of the arm (heat-transfer fluids)

- Thermal insulation

- Couplers for the connection to the top of the tanker

- Emergency disconnector

- Specific paint finish

- Specific coatings on request

- Atex archiving

Not suitable for food applications (no FDA compatibility) - For your food applications, see the product information sheet on Pacquet's Porteflex® hose holder (hose support system)

Specify ATEX zoning if applicable - CE marking for pneumatic, electrical equipment, or equipment used in ATEX zone - Specify if the loading arm is subject to the EU pressure equipment directive