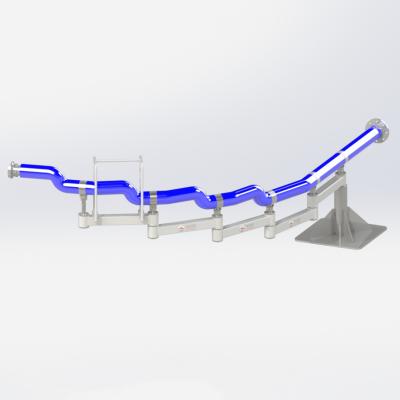

VARIABLE-REACH DRUM LOADING ARMS

For loading and unloading drums and IBC containers

For drums up to 220L and IBC containers up to 1000L

Ergonomic and light to handle

Strengths and specificities

- The Pacquet drum loading arm can load and unload up to 6 IBC containers and 10 barrels by simply moving the arm

- Has a large deployment area

- Drop pipe system available on request (for loading and unloading foaming fluids)

Conditions of use

The conditions of use depend on several factors (installation environment of the arms, service conditions and fluid characteristics). Let's find the right loading arm for you: send us your SDS (safety data sheets).

STANDARD TECHNICAL CHARACTERISTICS OF THE VARIABLE-REACH DRUM LOADING ARM

- Steel or stainless steel construction as standard

- Balancing using gas-spring compensators as standard

- Fastening to a bracket, wall or existing post (depending on the existing environment and structure)

- Top, bottom or side feed

OPTIONAL EQUIPMENT AVAILABLE

- Fastened with a support bracket

- Pneumatic assistance (helps with handling the drum loading arm)

- Vapour recovery duct

- Positioning cone or hood with flaps

- Single butterfly valve or double offset butterfly valve

- Ball valve

- Remotely controlled valve opening/closing control

- Drain valve

- Locking in loading position

- Locking in storage position

- Position detector

- Dead man command

- Electric tracing or double jacket heating of the arm (heat-transfer fluids)

- Thermal insulation

- Specific paint finish

- Specific coatings on request

- Atex archiving

FDA compatibility (food applications) available on request - Specify ATEX zoning if applicable - CE marking for pneumatic, electrical equipment, or equipment used in ATEX zone - Specify if the loading arm is subject to the EU pressure equipment directive